ISO 7432:2018

(Main)Glass-reinforced thermosetting plastics (GRP) pipes and fittings — Test methods to prove the design of locked socket-and-spigot joints, including double-socket joints, with elastomeric seals

Glass-reinforced thermosetting plastics (GRP) pipes and fittings — Test methods to prove the design of locked socket-and-spigot joints, including double-socket joints, with elastomeric seals

This document specifies methods of test for joints with a locked socket and spigot, including double-socket joints, and with elastomeric seals, for buried and above ground glass-reinforced thermosetting plastics (GRP) piping systems. It covers methods of test for leaktightness and resistance to damage of the joint only, when subjected to specified combinations of angular movement, compression (deformation) perpendicular to the pipe axis and internal pressure. It assumes that the joint will be exposed to the effects of hydrostatic end thrust. This document is applicable to joints for either pressure or non-pressure applications. The tests are suitable for the evaluation of joints intended for applications in which the liquids are conveyed at temperatures specified in the referring standards. The joints tested in accordance with this document are subjected to conditions which measure their ability to function and thereby prove the design of the joint, especially for type test purposes. The joint is only qualified according to the test sequences and configurations detailed in this document. With the exception of the bending test (see 9.5), the test procedures are applicable to joints for pipes and fittings of all nominal sizes. If not otherwise agreed between the manufacturer and the customer, the bending test detailed in 9.5 is applicable to joints with pipes and fittings up to and including DN 600. The test procedures in this document are damaging to the test piece, which will not be suitable for reuse after these tests. The test procedure is intended to be applied for type testing purposes. This document is applicable only to the joint and specifies methods of test to prove its design.

Tubes et raccords en plastiques thermodurcissables renforcés de verre (PRV) — Méthodes d'essai pour confirmer la conception des assemblages mâle-femelle verrouillés, y compris ceux à double emboîture avec joints d'étanchéité en élastomère

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 7432

Second edition

2018-09

Glass-reinforced thermosetting

plastics (GRP) pipes and fittings —

Test methods to prove the design

of locked socket-and-spigot joints,

including double-socket joints, with

elastomeric seals

Tubes et raccords en plastiques thermodurcissables renforcés de

verre (PRV) — Méthodes d'essai pour confirmer la conception des

assemblages mâle-femelle verrouillés, y compris ceux à double

emboîture avec joints d'étanchéité en élastomère

Reference number

ISO 7432:2018(E)

©

ISO 2018

---------------------- Page: 1 ----------------------

ISO 7432:2018(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 7432:2018(E)

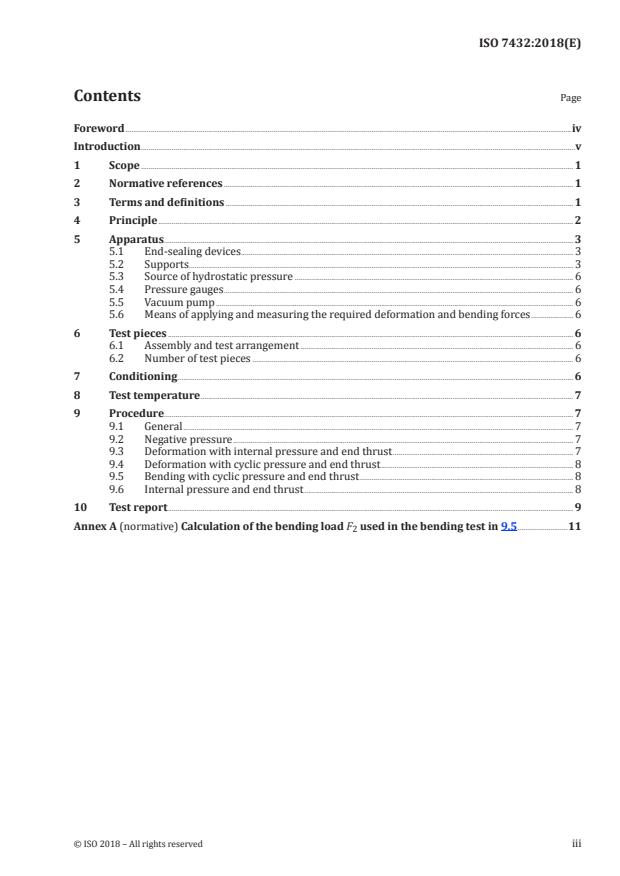

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 2

5 Apparatus . 3

5.1 End-sealing devices. 3

5.2 Supports . 3

5.3 Source of hydrostatic pressure . 6

5.4 Pressure gauges. 6

5.5 Vacuum pump . 6

5.6 Means of applying and measuring the required deformation and bending forces . 6

6 Test pieces . 6

6.1 Assembly and test arrangement . 6

6.2 Number of test pieces . 6

7 Conditioning . 6

8 Test temperature . 7

9 Procedure. 7

9.1 General . 7

9.2 Negative pressure . 7

9.3 Deformation with internal pressure and end thrust . 7

9.4 Deformation with cyclic pressure and end thrust . 8

9.5 Bending with cyclic pressure and end thrust . 8

9.6 Internal pressure and end thrust . 8

10 Test report . 9

Annex A (normative) Calculation of the bending load F used in the bending test in 9.5 .11

2

© ISO 2018 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 7432:2018(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 138, Plastics pipes, fittings and valves for

the transport of fluids, Subcommittee SC 6, Reinforced plastics pipes and fittings for all applications.

This second edition cancels and replaces the first edition (ISO 7432:2002), which has been technically

revised.

This edition includes the following significant changes compared to the previous edition:

— changed Scope to mention that the test procedure is a destructive test;

— terms and definitions clause added to this document;

— changed testing sequences from mandatory to recommended;

— changed wording from “misalignment” to “deformation”;

— modified test sequence for the proof of the design (Clause 9);

— changes in Table 1 with modified testing sequences for the proof of the design of joints;

— modification of bending test sequence.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

iv © ISO 2018 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 7432:2018(E)

Introduction

In a pipework system, pipes and fittings of different nominal pressures and nominal stiffnesses may

be used.

A joint may be made between pipes and/or fittings and should be designed such that its performance

is equal to or better than the requirements for the pipeline, but not necessarily for the components

being joined.

The requirements for the assembly of the joint are not included in this document, but they should be in

accordance with the manufacturer’s recommendations.

The material-dependent parameters and/or performance requirements are stated in the referring

standard.

© ISO 2018 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 7432:2018(E)

Glass-reinforced thermosetting plastics (GRP) pipes and

fittings — Test methods to prove the design of locked

socket-and-spigot joints, including double-socket joints,

with elastomeric seals

1 Scope

This document specifies methods of test for joints with a locked socket and spigot, including double-

socket joints, and with elastomeric seals, for buried and above ground glass-reinforced thermosetting

plastics (GRP) piping systems. It covers methods of test for leaktightness and resistance to damage of the

joint only, when subjected to specified combinations of angular movement, compression (deformation)

perpendicular to the pipe axis and internal pressure. It assumes that the joint will be exposed to the

effects of hydrostatic end thrust.

This document is applicable to joints for either pressure or non-pressure applications. The tests are

suitable for the evaluation of joints intended for applications in which the liquids are conveyed at

temperatures specified in the referring standards.

The joints tested in accordance with this document are subjected to conditions which measure their

ability to function and thereby prove the design of the joint, especially for type test purposes. The joint

is only qualified according to the test sequences and configurations detailed in this document.

With the exception of the bending test (see 9.5), the test procedures are applicable to joints for pipes

and fittings of all nominal sizes. If not otherwise agreed between the manufacturer and the customer,

the bending test detailed in 9.5 is applicable to joints with pipes and fittings up to and including DN 600.

The test procedures in this document are damaging to the test piece, which will not be suitable for

reuse after these tests. The test procedure is intended to be applied for type testing purposes.

This document is applicable only to the joint and specifies methods of test to prove its design.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http: //www .electropedia .org/

— ISO Online browsing platform: available at http: //www .iso .org/obp

3.1

pressure

hydrostatic gauge pressure

Note 1 to entry: Expressed in bar.

3.2

bending

bending in the pipe and coupling configuration as a result of a vertical force on the coupling

© ISO 2018 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 7432:2018(E)

3.3

deformation

pipe deformation in the coupling as a result of a vertical force on the pipe and a supported coupling

causing a step between the two pipe spigots at the loading position

4 Principle

A test piece comprising two pieces of pipe jointed together, by incorporation of a socket or inclusion of a

double-socket coupler, is subjected to specified load conditions, including combinations of bending and

deformation. In each specified combination the test piece is subjected to a series of test pressures for

specified periods of time, including an internal sub-atmospheric test pressure. This also simulates an

external positive pressure.

In addition, a test at elevated positive static pressure is conducted to prove the structural design of the

coupling (see Table 1 and 9.6).

In the tests detailed in 9.5 the joint is subjected to a bending load of such a magnitude that the axial

tensile stress in the pipe is equal to that developed from a pressure of 0,5 times PN [see Formula (1)].

01,[PN](×+de)

i

σ =05, (1)

b

4e

In addition, the joint is then pressure tested at 1,5 times PN, which then results in a total axial stress

(bending plus pressure), σ , equivalent to 2 times PN, i.e.:

ax

01,[PN]×d

i

σ = (2)

ax

2e

When under pressure, the joint is monitored for leakage. After each test condition (see Table 1) the joint

is inspected for signs of damage.

NOTE 1 The only reason for testing the joint for resistance to negative pressure is to ensure adequate safety

against infiltration of pollutants through the joint into the fluid carried in the piping system. Under the test

conditions used, pipes with low stiffness can require support to prevent buckling.

NOTE 2 If not otherwise specified, the ISO product standards ISO 10639, ISO 10467 and ISO 25780 specify the

following test parameter. It is assumed these test parameters are also set by other applicable product standards.

If this is not the case the parameters detailed in this document and in ISO 10639, ISO 10467 as well as ISO 25780

can be used as default values.

NOTE 3 It is assumed that the following test parameters are set by the standard making reference to this

document:

— the nominal size of the components to be connected by the joint (see 6.1);

— the pressure class of the components (see 6.1);

— the total effective length, L, of the test piece (see 6.1);

— the number of test pieces (see 6.2);

— if applicable, the conditioning to be applied (see Clause 7);

— the test temperature (see Clause 8);

— the sequence of testing, if appropriate (see 9.1);

— the test configuration (see Table 1);

— the deformation and bending forces F and F (see 9.3, 9.4, 9.5, and 9.6);

1 2

— the permissible change in negative pressure (see 9.2.3).

2 © ISO 2018 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 7432:2018(E)

5 Apparatus

5.1 End-sealing devices

The end sealing devices shall be of sizes and type appropriate to the components under test. The end-

sealing devices shall be securely fixed to the pipes to transmit the end thrust loads to the pipes.

5.2 Supports

5.2.1 Straps or cradles, for use as follows:

a) a support R (item 6 in Figure 2) positioned at least 500 mm from the spigot end of the pipe at the

point of balance to provide support during testing with deformation (see 9.3 and 9.4);

b) a strap or cradle (100 ± 5) mm wide (item 7 in Figure 2) supporting at least a 120° arc of the

socket, as required for deformation testing (see 9.3 and 9.4);

c) a strap or cradle (100 ± 5) mm wide supporting an arc up to 180° of the pipe barrel, positioned

adjacent to the end of the joint being tested (item 5 in Figure 2) and through which the force F

1

necessary for deformation testing (see 9.3 and 9.4) can be applied;

d) a strap or cradle (100 ± 5) mm wide supporting an arc up to 180° of the pipe barrel, positioned in

the middle of the joint being tested (item 5 in Figure 3) and through which the force F necessary

2

for the bending test (see 9.5) can be applied;

e) supports of sufficient width to carry the pipe components of the test piece (item 3 in Figure 2) and

designed in such a way that they allow

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.