ISO 28706-5:2008

(Main)Vitreous and porcelain enamels — Determination of resistance to chemical corrosion — Part 5: Determination of resistance to chemical corrosion in closed systems

Vitreous and porcelain enamels — Determination of resistance to chemical corrosion — Part 5: Determination of resistance to chemical corrosion in closed systems

ISO 28706-5:2008 specifies a test method for the determination of the resistance of vitreous and porcelain enamelled articles to attack in closed systems by acid, neutral and alkaline liquids, as well as by actual process mixes. It applies primarily to the testing of enamels designed for use in chemical processes.

Émaux vitrifiés — Détermination de la résistance à la corrosion chimique — Partie 5: Détermination de la résistance à la corrosion chimique en milieux fermés

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 28706-5

First edition

2008-12-01

Vitreous and porcelain enamels —

Determination of resistance to chemical

corrosion —

Part 5:

Determination of resistance to chemical

corrosion in closed systems

Émaux vitrifiés — Détermination de la résistance à la corrosion

chimique —

Partie 5: Détermination de la résistance à la corrosion chimique en

milieux fermés

Reference number

ISO 28706-5:2008(E)

©

ISO 2008

---------------------- Page: 1 ----------------------

ISO 28706-5:2008(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2008 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 28706-5:2008(E)

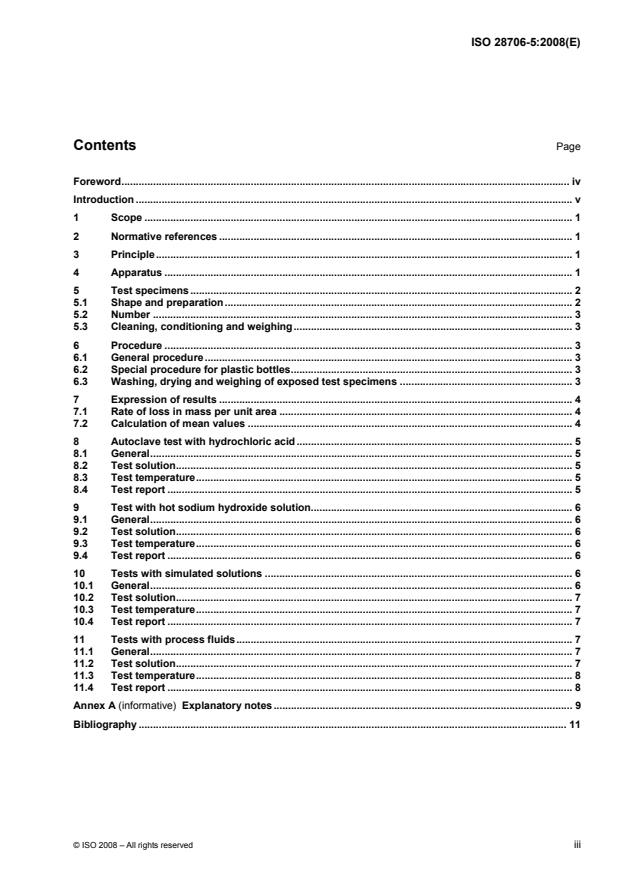

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Principle. 1

4 Apparatus . 1

5 Test specimens . 2

5.1 Shape and preparation. 2

5.2 Number . 3

5.3 Cleaning, conditioning and weighing. 3

6 Procedure . 3

6.1 General procedure. 3

6.2 Special procedure for plastic bottles. 3

6.3 Washing, drying and weighing of exposed test specimens . 3

7 Expression of results . 4

7.1 Rate of loss in mass per unit area . 4

7.2 Calculation of mean values . 4

8 Autoclave test with hydrochloric acid. 5

8.1 General. 5

8.2 Test solution. 5

8.3 Test temperature. 5

8.4 Test report . 5

9 Test with hot sodium hydroxide solution. 6

9.1 General. 6

9.2 Test solution. 6

9.3 Test temperature. 6

9.4 Test report . 6

10 Tests with simulated solutions . 6

10.1 General. 6

10.2 Test solution. 7

10.3 Test temperature. 7

10.4 Test report . 7

11 Tests with process fluids. 7

11.1 General. 7

11.2 Test solution. 7

11.3 Test temperature. 8

11.4 Test report . 8

Annex A (informative) Explanatory notes. 9

Bibliography . 11

© ISO 2008 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 28706-5:2008(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 28706-5 was prepared by the European Committee for Standardization (CEN) (as EN 14483-5) and was

adopted, under a special “fast-track procedure”, by Technical Committee ISO/TC 107, Metallic and other

inorganic coatings, in parallel with its approval by the ISO member bodies.

It cancels and replaces ISO 13806:1999, which has been technically revised.

ISO 28706 consists of the following parts, under the general title Vitreous and porcelain enamels —

Determination of resistance to chemical corrosion:

⎯ Part 1: Determination of resistance to chemical corrosion by acids at room temperature

⎯ Part 2: Determination of resistance to chemical corrosion by boiling acids, boiling neutral liquids and/or

their vapours

⎯ Part 3: Determination of resistance to chemical corrosion by alkaline liquids using a hexagonal vessel

⎯ Part 4: Determination of resistance to chemical corrosion by alkaline liquids using a cylindrical vessel

⎯ Part 5: Determination of resistance to chemical corrosion in closed systems

iv © ISO 2008 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 28706-5:2008(E)

Introduction

Corrosion of vitreous and porcelain enamels by aqueous solutions is a dissolution process. The main

component of the enamel, SiO , forms a three-dimensional silica network. After hydrolysis, it decomposes and

2

forms silicic acid or silicates. These are released into the attacking medium. Other components, mainly metal

oxides, are hydrolysed as well and form the corresponding hydrated metal ions or hydroxides. All corrosion

products are more or less soluble in the attacking medium. The whole process results in a loss in mass per

unit area.

For some aqueous solutions, the attack on the enamel proceeds linearly during the corrosion time; for other

aqueous solutions, the attack on the enamel proceeds in a logarithmic manner during the corrosion time. Only

2

for the first series of solutions can a scientifically exact rate of loss in mass per unit area (g/m⋅h) be

calculated as well as a corrosion rate (mm/year).

The most important parameters influencing aqueous corrosion of the enamel are the enamel quality, the

temperature and the pH-value. Inhibition effects resulting from the limited solubility of silica can also contribute.

The following list describes different types of enamel attack for different corrosion conditions:

a) In aqueous alkali solutions like 0,1 mol/l NaOH (see Clause 9 of ISO 28706-4:2008) the silica network of

the enamel is considerably attacked at 80 °C. Silicates and most of the other hydrolysed components are

soluble in the alkali. Attack proceeds linearly during regular test times. Therefore test results are

expressed in terms of a rate of loss in mass per unit area (mass loss per unit area and time) and a

corrosion rate (millimetres per year).

b) At room temperature, in weak aqueous acids like citric acid (see Clause 9 of ISO 28706-1:2008) or also in

stronger acids like sulfuric acid (see Clause 10 of ISO 28706-1:2008), there is only minor attack on the

silica network of the enamel. Other constituents are leached to some extent from the surface. Highly

resistant enamels will show no visual change after exposure. On less resistant enamels, some staining or

surface roughening will occur.

c) In boiling aqueous acids (see ISO 28706-2), the silica network of the enamel is being attacked, and silica

as well as the other enamel components are released into solution. However, the solubility of silica in

acids is low. Soon, the attacking solutions will become saturated with dissolved silica and will then only

leach the surface. The acid attack is inhibited and the rate of corrosion drops markedly.

NOTE The glass test equipment also releases silica by acid attack and contributes to the inhibition of the

corrosion.

Inhibition is effectively prevented in vapour phase tests. The condensate formed on the test specimen is

free of any dissolved enamel constituents.

Examples of enamel corrosion proceeding in a logarithmic manner [see 1)] and linearly [see 2)] are:

1) Boiling citric acid (see Clause 10 of ISO 28706-2:2008) and boiling 30 % sulfuric acid (see

Clause 11 of ISO 28706-2:2008)

Since only minute amounts of these acids are found in their vapours, the test is restricted to the liquid

phase. The attack is influenced by inhibition effects, and corrosion depends on the time of exposure.

Therefore, test results are expressed in terms of loss in mass per unit area; no rate of loss in mass

per unit area is calculated.

© ISO 2008 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 28706-5:2008(E)

2) Boiling 20 % hydrochloric acid (see Clause 12 of ISO 28706-2:2008)

Since this is an azeotropic boiling acid, its concentration in the liquid and the vapour phase are

identical, and liquid phase testing need not be performed. Vigorous boiling supplies an uninhibited

condensate, and the attack proceeds linearly with time of exposure. Therefore, test results are only

expressed in terms of rate of loss in mass per unit area (mass loss per unit area and time) and the

corrosion rate (millimetres per year).

d) At high temperatures, with tests in the liquid phase under autoclave conditions (see ISO 28706-5),

aqueous acid attack is severe. To avoid inhibition, the test time is restricted to 24 h and the ratio of

attacking acid to attacked enamel surface is chosen so that it is comparatively high (similar to that in a

chemical reaction vessel). In addition, only low-silica water is used for the preparation of test solutions.

Under these conditions, attack will proceed linearly with time of exposure. Therefore, test results with

20 % hydrochloric acid (see Clause 8 of ISO 28706-5:2008), simulated test solutions (see Clause 10 of

ISO 28706-5:2008) or process fluids (see Clause 11 of ISO 28706-5:2008) are also expressed in terms of

a rate of loss in mass per unit area (loss in mass per unit area and time).

e) In boiling water (see Clause 13 of ISO 28706-2:2008), the silica network is fairly stable. The enamel

surface is leached and silica is dissolved only to a small extent. This type of attack is clearly represented

by the vapour phase attack. In the liquid phase, some inhibition can be observed with highly resistant

enamels. However, if the enamel being tested is weak, leached alkali from the enamel can raise

pH-values to alkaline levels, thus increasing the attack by the liquid phase. Both liquid and vapour phase

testing can give valuable information.

f) Since the attack may or may not be linear, the results are expressed only in terms of loss in mass per unit

area, and the test time should be indicated.

g) For standard detergent solution (see Clause 9 of ISO 28706-3:2008), it will not be certain whether the

linear part of the corrosion curve will be reached during testing for 24 h or 168 h. Calculation of the

corrosion rate is therefore not included in the test report.

h) For other acids (see Clause 14 of ISO 28706-2:2008) and other alkaline solutions (see Clause 10 of

ISO 28706-3:2008 and Clause 10 of ISO 28706-4:2008), it will also not be known if a linear corrosion rate

will be reached during the test period. Calculation of the corrosion rate is therefore not included in the test

reports of those parts of this International Standard.

For vitreous enamels fired at temperatures below 700 °C, the test parameters (media, temperatures and

times) of this International Standard are not appropriate. For such enamels, for example aluminium enamels,

other media, temperatures and/or times should be used. This can be done following the procedures described

in the clauses for “Other test solutions” in Parts 1, 2, 3 and 4 of this International Standard.

vi © ISO 2008 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 28706-5:2008(E)

Vitreous and porcelain enamels — Determination of resistance

to chemical corrosion —

Part 5:

Determination of resistance to chemical corrosion in closed

systems

1 Scope

This part of ISO 28706 specifies a test method for the determination of the resistance of vitreous and

porcelain enamelled articles to attack in closed systems by acid, neutral and alkaline liquids, as well as by

actual process mixes.

It applies primarily to the testing of enamels designed for use in chemical processes.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 649-1, Laboratory glassware — Density hydrometers for general purposes — Part 1: Specification

ISO 3696, Water for analytical laboratory use — Specification and test methods

3 Principle

Enamelled test specimens are exposed in an autoclave, under defined conditions, to attack by a liquid which

is corrosive at temperatures above its normal boiling point.

The loss in mass is determined and used to calculate the rate of loss in mass per unit area.

4 Apparatus

4.1 Test vessel

4.1.1 Design

The ratio between the volume, V, of the test solution, in cubic centimetres, at 20 °C, and the exposed area of

enamel, A, in square centimetres, shall be V/A = (40 ± 2) cm. The vessel shall be filled to a level such that,

when closed and given an ambient temperature of 18 °C to 28 °C, at least 20 % of its volume remains

available as a vapour headspace. To ensure this requirement is met, the size of the test apparatus shall be

selected to suit that of the specimen.

© ISO 2008 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 28706-5:2008(E)

NOTE Several enamelled specimens can be placed in the same test vessel and tested simultaneously.

WARNING — The test vessel may be a pressure vessel. Attention is drawn to national and

international regulations regarding the safe use of pressure vessels.

4.1.2 Material

The test vessel shall be made of a material resistant to the test solution and not releasing any substances that

might influence the corrosion of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.